When buying impact gloves in bulk, ensuring safety, quality, and cost-effectiveness is critical. Whether you’re purchasing for construction, oil and gas, or heavy-duty industries, understanding what to look for can help you make smarter decisions.

What Should B2B Buyers Consider When Ordering Impact Gloves in Bulk?

B2B buyers should focus on certifications, material quality, fit, supplier reliability, and cost-effectiveness when ordering impact gloves in bulk. These factors ensure the gloves meet safety standards and align with your operational needs.

1. Ensure Compliance with Safety Standards

Certifications like ANSI/ISEA 138 (impact resistance) and EN 388 (mechanical risks) are essential. These standards verify that gloves provide adequate protection against hazards like blunt force, cuts, and abrasions. Choose gloves that meet or exceed these standards to ensure worker safety.

2. Prioritize Material Quality and Durability

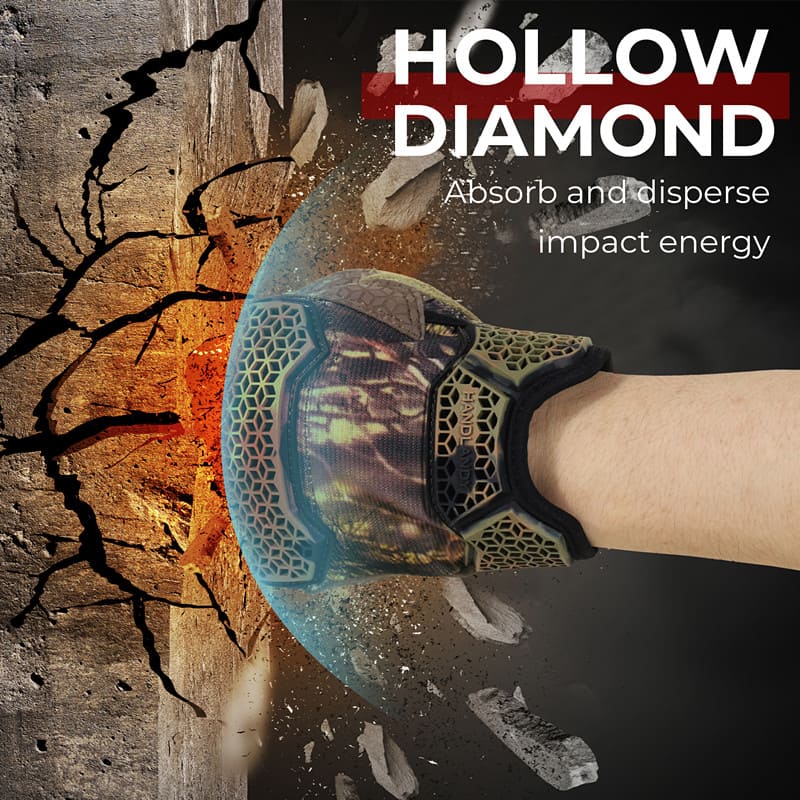

- High-Quality Materials: Look for gloves made with thermoplastic rubber (TPR) for impact resistance and durable fabrics for longevity.

- Resistance to Wear and Tear: Select gloves that can withstand demanding environments, reducing the need for frequent replacements.

| Material | Benefits |

|---|---|

| Thermoplastic Rubber (TPR) | Absorbs and disperses impacts |

| Reinforced Leather | Increases durability |

| Flexible Fabrics | Improves comfort and dexterity |

3. Choose the Right Design for Your Industry

Different industries have different needs, so the glove design should match your operational requirements:

- Construction: Reinforced knuckles and padded palms for handling tools and heavy materials.

- Oil and Gas: Grip-enhancing features for wet or oily environments.

- Manufacturing: Flexible materials for precision work.

4. Verify Supplier Reliability

Choose a supplier with a proven track record for delivering high-quality products on time. Request samples to test the gloves before committing to a bulk purchase. Evaluate the supplier’s communication, production capacity, and reviews to ensure they can meet your demands.

5. Evaluate Bulk Pricing and Cost-Effectiveness

Buying in bulk typically reduces per-unit costs. However, avoid compromising on quality for savings. Compare multiple suppliers and negotiate favorable terms to maximize value.

| Quantity Ordered | Discount (%) |

|---|---|

| 1000-5000 units | 10-15% |

| 5001-10,000 units | 20-25% |

| 10,001+ units | 30%+ |

6. Consider Proper Fit and Sizing

Ill-fitting gloves can lead to discomfort and reduced protection. Provide a range of sizes to ensure all workers have a proper fit. Some suppliers offer custom sizing for bulk orders, which can enhance comfort and safety.

7. Review Packaging and Storage Requirements

Ensure that gloves are packaged securely to prevent damage during transit. Bulk orders should include clear labeling and easy storage solutions to streamline inventory management.

8. Plan Inventory Management

Efficient inventory management is essential to avoid shortages or overstocking. Implement systems to track glove usage and ensure timely reorders to prevent downtime.

Conclusion

When buying impact gloves in bulk, prioritize certifications, material quality, fit, and supplier reliability to ensure safety and cost-effectiveness. By focusing on these key factors, B2B buyers can select gloves that meet safety standards, provide long-term value, and keep workers protected.

Taking the time to evaluate these considerations will help you make an informed decision and optimize your investment in bulk impact gloves.