Impact gloves are essential for protecting workers in industries like construction, oil & gas, and manufacturing. The technology behind these gloves is constantly evolving to offer better protection, comfort, and efficiency. Below are the top trends in impact glove technology that will shape the market in 2025.

1. Enhanced Impact Protection with New Materials

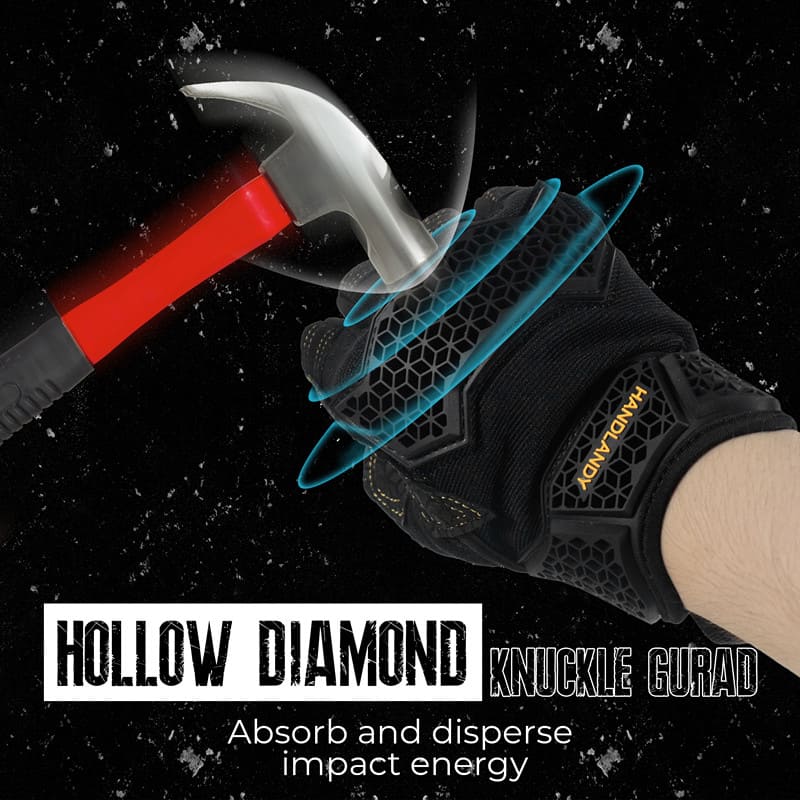

One of the most significant trends is the use of advanced materials like thermoplastic rubber (TPR), which offers flexible yet strong impact protection. TPR is widely used in gloves to create protective zones around knuckles and fingers without sacrificing comfort or dexterity.

Why It Matters: These gloves are becoming lighter and more comfortable while maintaining or even improving impact resistance. This is crucial for industries where hand protection is a daily need, ensuring workers can move freely while staying safe from injuries.

What to Expect: New material advancements like graphene-enhanced compounds will likely emerge, providing even stronger protection at a lighter weight.

2. Improved Ergonomics and Custom-Fit Designs

Comfort is becoming a top priority, especially for workers who wear gloves for long hours. Manufacturers are focusing on creating gloves with better ergonomics, which include soft-shell materials, flexible joints, and breathable fabrics.

Why It Matters: Ergonomic designs help reduce hand fatigue, increase productivity, and prevent repetitive strain injuries. Gloves that fit well are more likely to be worn correctly, ensuring maximum protection.

Future Outlook: Expect to see more gloves designed with 3D printing technology or custom-fit solutions, allowing for a tailored fit to individual hand shapes.

3. Multi-Layered Cut and Puncture Resistance

While impact protection is critical, many industries also require cut and puncture resistance. Gloves are now being made with materials like Kevlar and ultra-high molecular weight polyethylene (UHMWPE), providing dual protection against both sharp objects and blunt force.

Why It Matters: In sectors like construction or warehousing, where both impact and sharp materials are common hazards, having gloves that offer comprehensive protection is essential. This reduces the risk of injuries and minimizes downtime.

What to Expect: Future gloves will integrate these protections more seamlessly, offering lightweight designs that do not sacrifice flexibility or comfort.

4. Sustainability in Glove Production

As sustainability becomes a global priority, glove manufacturers are adopting eco-friendly materials and production processes. This includes the use of recycled rubber and biodegradable components.

Why It Matters: Customers are increasingly concerned about the environmental impact of their purchases, and industries are moving towards greener solutions. Gloves that meet safety standards while reducing environmental harm are becoming more appealing to buyers.

What to Expect: More gloves made from recyclable or biodegradable materials, without compromising on durability or protection, will enter the market.

5. Smart Impact Gloves with Integrated Sensors

The integration of smart technology into impact gloves is gaining traction. These gloves are equipped with sensors that monitor hand movements, pressure, and even environmental conditions, providing real-time data to enhance safety.

Why It Matters: This technology helps detect unsafe conditions early, such as overexertion or exposure to extreme temperatures. By providing instant feedback, smart gloves can prevent accidents before they happen.

What to Expect: As technology improves, these sensors will become more affordable and widespread, making smart impact gloves a common tool for safety monitoring in various industries.

6. Customizable Impact Zones

Another growing trend is the ability to customize the impact protection zones on gloves. Different tasks require different levels of protection, and manufacturers are now offering gloves where users can adjust padding based on the job at hand.

Why It Matters: This flexibility allows workers to get the protection they need for specific tasks, without the bulk of overbuilt gloves for lighter jobs. This customization improves both safety and comfort.

What to Expect: Gloves with removable or adjustable protection pads will become more common, allowing one pair of gloves to be used for multiple types of work.

7. Lightweight Designs with Maximum Protection

Workers want gloves that offer top-notch protection without being bulky or heavy. The trend towards lightweight designs is pushing manufacturers to develop gloves that are thinner and more comfortable while maintaining high levels of impact resistance.

Why It Matters: Lighter gloves reduce hand strain, improve mobility, and make it easier to perform tasks that require fine motor skills. This is particularly important in industries where precision and safety go hand in hand.

What to Expect: Expect to see more thin, flexible gloves that provide the same level of protection as their bulkier counterparts, thanks to advancements in material science.

Conclusion

The impact glove industry is evolving rapidly, with new technologies enhancing safety, comfort, and sustainability. From smart gloves with integrated sensors to lightweight, eco-friendly materials, the future of hand protection is looking brighter. Businesses should keep these trends in mind when sourcing gloves for their teams to ensure they are providing the best possible protection for their workers.

If you’re looking to upgrade your impact gloves or explore custom solutions, now is the time to explore these cutting-edge technologies.