When it comes to choosing impact gloves, the materials used play a critical role in determining their durability and level of protection. The right materials not only ensure safety but also improve comfort and usability in demanding work environments. Below are the top five materials commonly used in high-quality impact gloves and why they matter.

What Are the Top Materials for Durable and Protective Impact Gloves?

The top materials for impact gloves are thermoplastic rubber (TPR), leather, Kevlar, nitrile, and neoprene. Each material offers unique benefits like impact absorption, durability, or chemical resistance, ensuring optimal protection and performance.

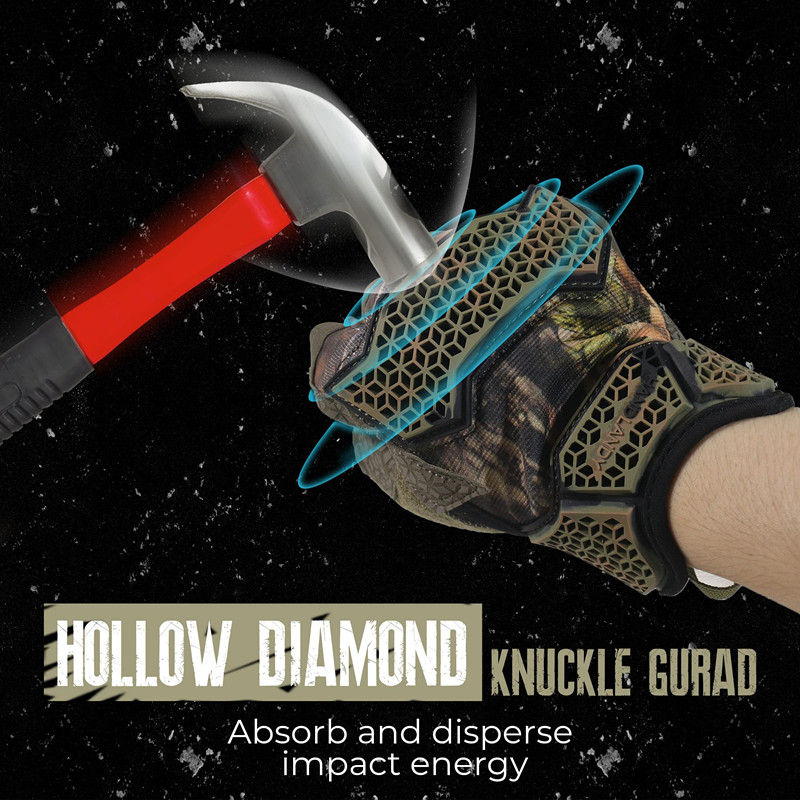

1. Thermoplastic Rubber (TPR)

- Properties: Flexible, durable, and excellent at absorbing and dispersing impact energy.

- Use in Gloves: TPR is typically used on the back of gloves to protect knuckles, fingers, and other vulnerable areas from impacts and crushing forces.

- Why It’s Essential: It adds a layer of safety in industries like construction, oil and gas, and manufacturing without compromising flexibility.

2. Leather

- Properties: Naturally durable, abrasion-resistant, and comfortable.

- Use in Gloves: Leather is often used for the palms and fingers to enhance grip and protect against cuts and punctures.

- Why It’s Essential: Its combination of strength and dexterity makes it ideal for heavy-duty tasks like welding, rigging, and general industrial work.

3. Kevlar

- Properties: High tensile strength and excellent cut resistance.

- Use in Gloves: Kevlar is integrated into glove liners or outer layers for protection against sharp objects and heat.

- Why It’s Essential: Kevlar gloves are particularly suitable for industries involving sharp tools, glass handling, or extreme temperatures.

4. Nitrile

- Properties: Resistant to punctures, chemicals, and oils, with a durable and grippy surface.

- Use in Gloves: Nitrile coatings are applied to the palms to improve grip and protect hands from oil, grease, and chemical exposure.

- Why It’s Essential: Perfect for oil and gas, automotive, and industrial cleaning applications.

5. Neoprene

- Properties: Flexible, heat-resistant, and resistant to oils and chemicals.

- Use in Gloves: Neoprene is often used in cuffs or as part of the glove’s back to improve comfort and provide additional protection.

- Why It’s Essential: Its versatility and resistance to harsh elements make it ideal for gloves used in manufacturing, food processing, and laboratory settings.

Comparison Table: Materials for Impact Gloves

| Material | Key Benefits | Best Uses |

|---|---|---|

| Thermoplastic Rubber (TPR) | Impact absorption and flexibility | Construction, oil and gas, heavy machinery |

| Leather | Abrasion resistance and grip | Welding, rigging, general industrial work |

| Kevlar | Cut and heat resistance | Glass handling, sharp tools, extreme heat |

| Nitrile | Chemical and oil resistance, grip | Automotive, oil and gas, cleaning |

| Neoprene | Heat and chemical resistance | Manufacturing, food processing, lab work |

How to Choose the Right Material for Your Needs

- Assess Your Work Environment:

- High-impact tasks? Choose gloves with TPR.

- Handling sharp tools? Kevlar is the best option.

- Consider Weather and Conditions:

- Wet or oily environments require nitrile-coated gloves.

- Hot environments benefit from neoprene or Kevlar gloves.

- Balance Comfort and Protection:

- Leather offers a good balance of comfort and durability for general use.

- TPR provides added safety without sacrificing flexibility.

Conclusion

The top materials for impact gloves—TPR, leather, Kevlar, nitrile, and neoprene—offer unique benefits like durability, impact absorption, and chemical resistance, making them ideal for various industries and tasks. By understanding the strengths of these materials, you can select gloves that ensure safety, comfort, and long-term performance for your team.

Choosing the right gloves starts with selecting the best materials for the job. Ensure your workers have the protection they need by considering the specific hazards of your work environment.